As a desktop motherboard repair technician, you know how challenging it can be to diagnose and repair chip-level faults on modern motherboards. The ASRock DL-E35LM1 is a popular motherboard among PC enthusiasts, but when it comes to troubleshooting, its complexity can be daunting. Fortunately, the DL-E35LM1 R2.0 BoardView File is here to simplify the process. In this blog, we’ll explore how this invaluable tool can help you streamline your repair workflow, save time, and increase your success rate when fixing the ASRock DL-E35LM1 motherboard.

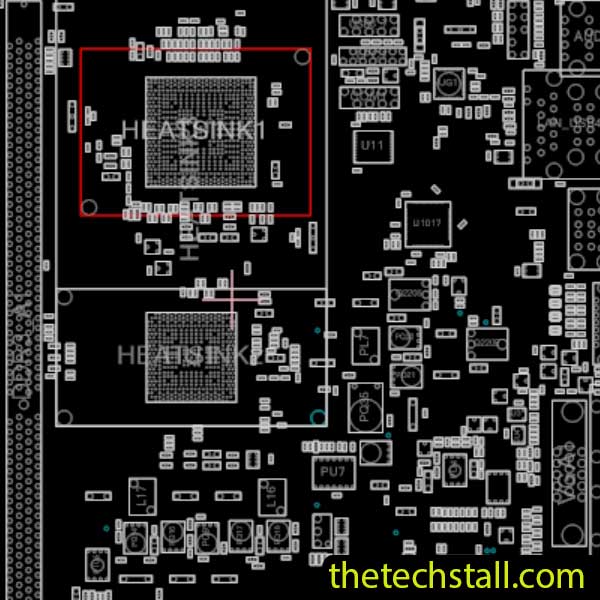

A BoardView file is a digital representation of a motherboard’s PCB layout. It provides a detailed schematic of the board, including component placements, trace paths, and test points. For technicians, this is an essential tool for diagnosing and repairing chip-level faults. Instead of relying solely on physical inspection or trial-and-error methods, a BoardView file allows you to pinpoint issues with precision.

The DL-E35LM1 R2.0 BoardView File is specifically designed for the ASRock DL-E35LM1 motherboard. It offers a comprehensive view of the board’s architecture, making it easier to identify faulty components, trace electrical pathways, and verify connections.

The ASRock DL-E35LM1 is a high-performance motherboard, but like any electronic device, it’s prone to chip-level faults. Some of the most common issues include:

Without a BoardView file, diagnosing these issues can be time-consuming and frustrating. However, with the DL-E35LM1 R2.0 BoardView File, you can quickly locate the problem areas and take corrective action.

Here’s how the DL-E35LM1 R2.0 BoardView File can make your repair process faster and more efficient:

The BoardView file provides a detailed map of the motherboard’s components, including resistors, capacitors, ICs, and connectors. This eliminates guesswork and ensures you’re working on the correct part of the board.

When dealing with signal integrity issues or short circuits, tracing the problem manually can be tedious. The BoardView file allows you to follow the trace paths digitally, saving you hours of work.

By cross-referencing the BoardView file with your multimeter or oscilloscope readings, you can confirm whether a component or trace is faulty. This reduces the risk of misdiagnosis and ensures you’re replacing the right parts.

Having access to the BoardView file gives you a deeper understanding of the motherboard’s design. This knowledge boosts your confidence and enables you to tackle even the most complex repairs.

To get the most out of the DL-E35LM1 R2.0 BoardView File, follow these steps:

The DL-E35LM1 R2.0 BoardView File is more than just a tool—it’s a game-changer for motherboard repair technicians. Here’s why:

To help you get started, we’re offering the DL-E35LM1 R2.0 BoardView File for free! Simply click the link below to download the file and take your motherboard repair skills to the next level.

Download “ASRock DL-E35LM1 R2.0 BoardView File” view – Downloaded 236 times – 33.95 KBRepairing the ASRock DL-E35LM1 motherboard doesn’t have to be a daunting task. With the DL-E35LM1 R2.0 BoardView File, you can simplify the process, save time, and achieve better results. Whether you’re a seasoned technician or just starting out, this tool is a must-have for your repair toolkit.

For tips on chip-level repair of laptop and desktop motherboards, visit our YouTube channel Repair Assistant and subscribe to our Facebook page repairassiastantbd for repair resource updates.

Don’t forget to download the file and share this blog with fellow technicians who might benefit from it. Happy repairing!

Share with friends

thetechstall.com would like to share with you all the resources you need to repair desktop and laptop motherboards for free.

Developed By: Ibrahim Hossen